Precision Alloys, Proven Durability, Superior Performance

SureAlloy® Stands Above

Premium Carbide Overlay Wear Plate | Chromium Carbide Plate | Complex Carbide Plate

Engineered for Maximum Wear Resistance

For over 70 years, SAS Global Corporation

(parent company of Cladtec) has been at the forefront of abrasion-resistant material innovation. Our proprietary

SureAlloy® Carbide Overlay Wear Plates are engineered for durability in the toughest industrial environments. Unlike off-the-shelf solutions,

SureAlloy® is manufactured using a precision-controlled process that ensures superior wear resistance, extended service life, and reduced maintenance downtime.

Every alloy in our SureAlloy® lineup is custom-blended in-house, giving us complete control over material quality—from formulation to final production. This guarantees a high-performance chromium carbide and complex carbide overlay plate that exceeds industry standards. Whether you're looking to minimize equipment wear or maximize operational efficiency, SureAlloy® delivers unmatched reliability for your most demanding applications.

SA6000®: The Future of Overlay Wear Plate Technology

Engineered for extreme wear and impact conditions, SA6000® sets a new standard in overlay wear plate performance. Its patented microstructure features a highly refined matrix of tightly packed complex carbides, delivering exceptional resistance to abrasion while significantly improving impact toughness.

SA6000®’s fine-grain microstructure minimizes crack propagation, ensuring longer service life and superior durability in demanding industrial applications. If you're looking for a wear solution that outperforms conventional materials in both abrasion resistance and impact strength, SA6000® is built to exceed expectations.

SA2000®: Advanced Wear Protection

SA2000® is an advanced complex carbide overlay plate that delivers superior wear resistance compared to conventional chromium carbide alloys. Its specially formulated microstructure generates a high concentration of small primary carbides, significantly reducing material loss and extending service life.

With harder, refined complex carbides, SA2000® not only improves wear resistance but also enhances toughness, temperature stability, and corrosion resistance. The presence of inert refractory carbides further increases heat tolerance, making it an ideal choice for demanding applications where standard chromium carbide plates fall short. Expect up to double the service life with SA2000.

SA1750CR®: Premium Chromium Carbide Overlay for Extreme Abrasion Resistance

Engineered for maximum durability in high-abrasion environments, SA1750CR® is a premium chromium carbide overlay plate featuring a hypereutectic matrix with 50-60% chromium carbides.

This exceptionally high concentration of hard chromium carbides provides superior resistance to wear and material loss, making SA1750CR® the ideal solution for applications where extreme abrasion is the primary cause of equipment failure.

Designed to withstand intense operational demands, SA1750CR® ensures longer service life, reduced maintenance, and improved overall efficiency in the harshest industrial conditions.

SA-MCC: Custom-Engineered Wear Solutions for Specific Applications

Designed to meet unique operational demands, SA-MCC offers a custom blended solution tailored for optimal wear resistance in specialized applications. By precisely adjusting the carbide composition, SA-MCC delivers targeted performance characteristics, ensuring superior durability in even the most challenging environments.

For example, applications requiring higher impact resistance and elevated temperature stability benefit from a blend rich in Molybdenum and Niobium, enhancing both toughness and heat tolerance. Whether your operation demands maximum abrasion resistance, extreme heat performance, or improved impact durability, SA-MCC provides a precision-engineered solution built to outperform conventional wear materials.

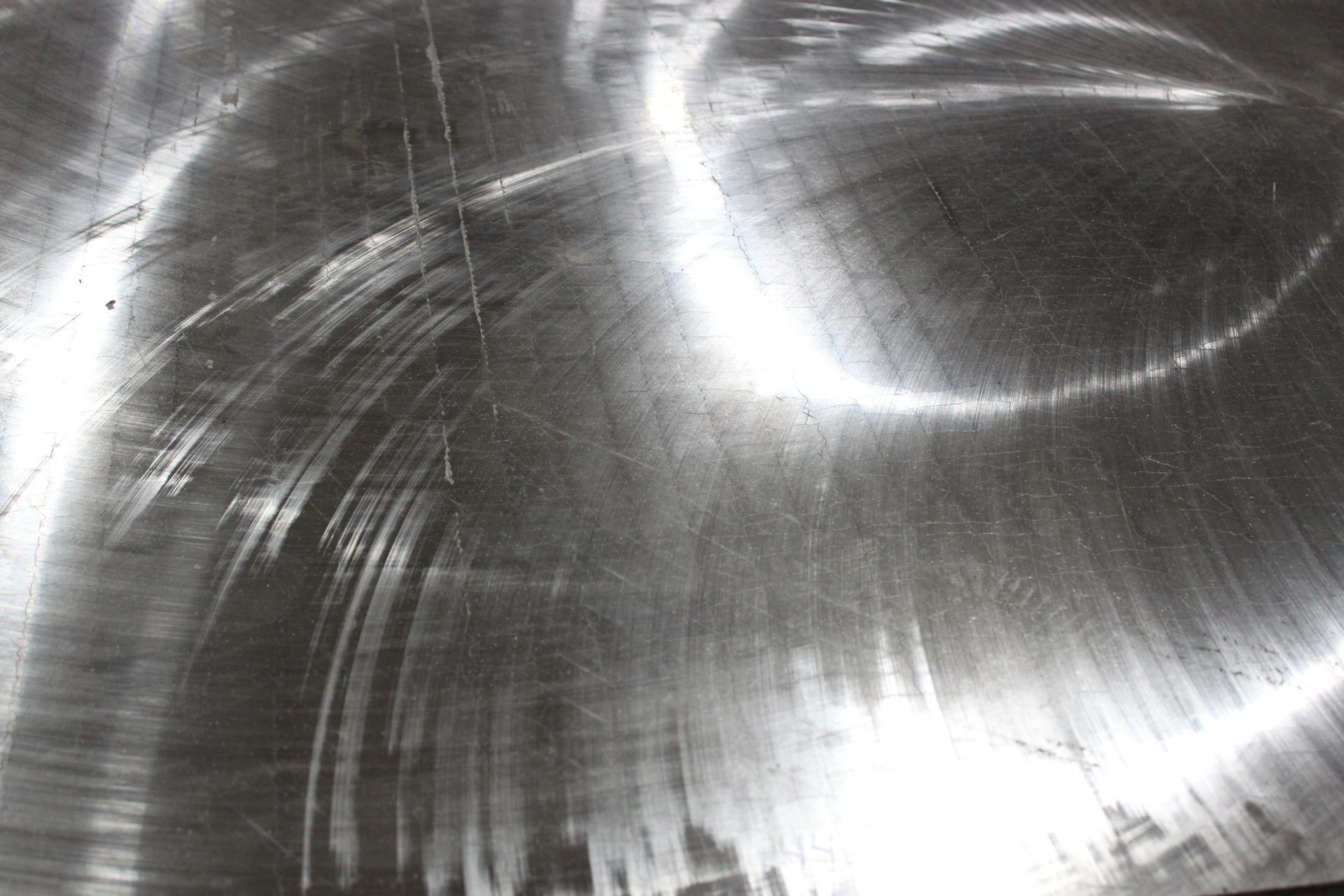

RapidFlow®: Ultra-Smooth Surface for Optimized Material Flow

SAS Global engineers a premium smooth surface finish on all SureAlloy® Weld Overlay Products to enhance performance in material handling applications. For operations experiencing heavy material hang-up, our RapidFlow® Premium Surface Carbide Overlay Plate provides an ultra-low friction solution that minimizes buildup / carryback and improves flow efficiency.

The RapidFlow® surface is blanchard ground, then precision-polished to a 0.2 Ra micro-meter finish, making it smoother than stainless steel 304 with a 2B finish. This advanced surface treatment reduces friction, extends equipment life, and optimizes throughput in demanding industrial environments. When material flow efficiency is critical, RapidFlow® delivers unmatched performance.

Available SureAlloy Thickness Combinations

Finished Plate Dimensions:

90" x 120" (3/16" thru 1" base plate)

(2.286m x 3.048m (4mm thru 25mm base plate))

90" x 240" (3/8" thru 1/2" base plate)

(2.286m x 6.096m (10mm thru 13mm base plate))

56" x 120" (1/8" overlay on 1/8" base plate)

(1.422m x 3.048m (3mm overlay on 3mm base plate))

Overlay Thicknesses with Thinner Base Plates:

• 1/2” (12mm) on 1/4” (6mm)

• 1/2” (12mm) on 3/8” (10mm)

• 5/8” (15mm) on 5/16” (8mm)

• 3/8” (10mm) on 1/4” (6mm)

• 3/4” (19mm) on 3/8” (10mm)

Do you want to increase the service life of your component / liner?

Simply fill out your information below to get started.