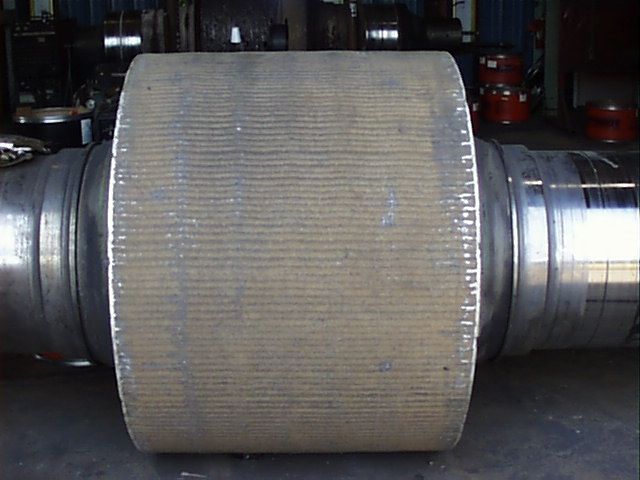

ROLLER PRESS REBUILDS AND HARDFACING

Restore Performance | Extend Service Life | Reduce Downtime

Cladtec delivers industry-leading wear-resistant rebuild services for roller press systems—helping plants maximize uptime and protect their investment in high-pressure grinding equipment. Our rebuilds aren’t just replacements—they’re engineered upgrades that consistently outlast the original OEM components.

CT-28 Hardfacing: Premium Restoration Material

At the heart of our roller press restoration process is Cladtec’s proprietary CT-28 chromium carbide hardfacing. This advanced material is specifically engineered for severe abrasion and impact conditions—restoring worn components with a surface that exceeds the original in both hardness and wear resistance.

We offer a range of specialized overlays to match the unique wear profiles of different feed materials and applications, ensuring the right protection for your roller press surfaces.

Benefits of a Cladtec Rebuild:

- Outlasts OEM Components – Engineered overlays outperform standard surfaces

- Significantly Increases Service Life – Less frequent changeouts and reduced total cost of ownership

- Minimizes Downtime – Fast turnaround with expert in-house and on-site service options

- Custom Wear Surface Options – Tailored to the exact abrasion and impact demands of your process

Whether you're running clinker, cement raw materials, or minerals, Cladtec’s roller press rebuilds deliver more uptime, better performance, and longer-lasting value.