RE-ENGINEERING THE DNA OF WEARPLATE

Patented Microstructure Complex Carbide Overlay Plate

The SA6000 wear plate from SAS Global is a cutting-edge complex carbide overlay plate, engineered with a patented microstructure. This unique microstructure features tightly packed complex carbides, significantly reducing crack propagation and enhancing both abrasion resistance and impact toughness beyond standard chromium carbide plates.

With a macro hardness of 65-68 HRC, SA6000 delivers 4X the wear life of conventional CCO plates, reducing maintenance downtime and replacement costs. Additionally, its superior impact resistance, verified through 5000 impacts of 20 Joules in testing, ensures durability in high-stress applications.

The advanced alloy composition allows for a 59% weight reduction while maintaining exceptional wear protection, making it ideal for heavy industries such as mining, power generation, steel, cement, and aggregate processing. SA6000 provides a versatile, long-lasting solution for industries requiring extreme durability in abrasive environments.

Nature's Symphony

The patented microstructure of SA6000 is highly refined with tightly packed complex carbides. This fine grain microstructure reduces the propagation of cracks, which results in superior impact resistance.

Faces of Humanity

For comparison, above is the microstructure of SA1750CR Chromium Carbide Overlay Plate. You can see the much larger carbides within the microstructure. These large carbides reduce the impact resistance of the material.

Maximize Performance and Minimize Downtime with SA6000

It's time to rethink wear solutions. SA6000 delivers 4X the service life of standard chromium carbide overlay (CCO) plate, drastically improving efficiency and reducing maintenance headaches.

- 4X the Wear Life – Extend equipment longevity and reduce replacement frequency.

- 59% Weight Reduction – 4mm of SA6000 replaces 12mm of standard CCO, optimizing load capacity.

- Increased Production – Less wear means more uptime and higher output.

- Lower Maintenance Costs – Fewer replacements translate to reduced labor and material expenses.

Upgrade to SA6000 and experience superior wear resistance without the extra weight. More durability, less downtime—because efficiency matters.

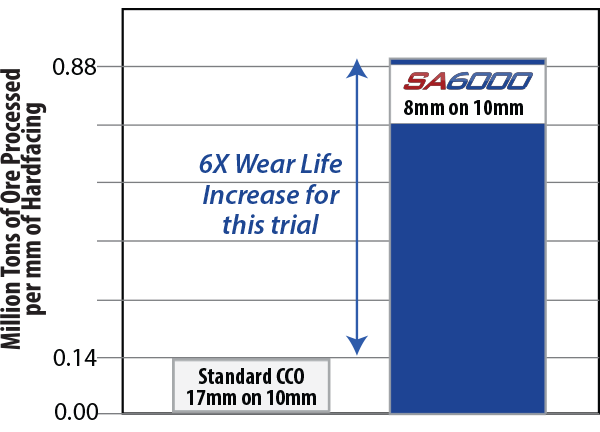

Ore Chute Case Study: SA6000 Delivers 6X the Wear Life of Standard Carbide Overlay Plate

In a head-to-head durability test within an ore processing chute, SA6000 significantly outperformed a standard chromium carbide overlay plate, delivering unmatched longevity and efficiency.

- SA6000 (8mm on 10mm): Lasted 2,795 hours, processing 7.09 million tons of ore.

- Standard Chromium Carbide Overlay (17mm on 10mm): Lasted an average of 949 hours, processing 2.48 million tons of ore.

The results? SA6000 provided six times the wear life, dramatically reducing downtime, maintenance, and replacement costs.

When performance matters, SA6000 is the clear choice.